Ski composition: (structure, core, construction)

The composition of an alpine ski may seem mysterious or even magical, but boring to understand…

And yet, it’s the key to understanding how a ski performs, what its energy is, its strengths and weaknesses, and most importantly, whether it’s the ski suited to your style and personality.

To really understand how a ski is built and what it’s made of, I’ll cover different aspects, including:

- the materials used

- the different types of cores

- the base

- the edges

- the top-sheet

A little extra as well about camber and rocker, which have become key features and an integral part of ski design—whether it’s for piste skis, freestyle, freeride, touring, or all-mountain skis.

Materials used

Not all skis use the same materials, and yet they all glide—but not in the same way!

This clearly means materials have different properties and influence the ski’s character.

Materials also affect a ski’s durability in terms of strength and performance.

Wood

Wood is the traditional material for ski cores, appreciated for its combination of lightness, durability, and vibration absorption.

Woods like maple, poplar, beech, ash, and aspen (also called trembling poplar) are commonly used, either alone or in combination, to balance flexibility and stiffness, thereby affecting power and responsiveness.

Fiberglass or carbon

Fiberglass is widely used in ski construction for adding stiffness and strength while remaining lightweight.

It often accounts for 50 to 80% of a ski’s overall stiffness.

Carbon fiber, on the other hand, is a lighter but more expensive alternative used to reduce total weight without sacrificing stiffness. It’s especially valued in touring skis, where weight is a crucial factor.

Metal

Metal, often in the form of aluminum sheets or alloys like Titanal, is integrated into some skis to boost power, stability, and damping capability.

It’s generally used in skis aimed at more aggressive skiers or hard snow conditions to improve edge grip.

High-density plastics

High-performance plastics are used in various ski components, including the base, top-sheet, and sidewalls.

Bases are usually made of UHMW-PE (ultra-high molecular weight polyethylene) for its excellent glide and durability against abrasion and impact.

The top-sheets (outer layers) protect the ski’s internal structure and provide space for graphics, while the sidewalls enhance durability and help transfer power between the skier and the ski edges.

By strategically combining these materials, ski manufacturers can create gear tailored to a wide range of skiing styles and snow conditions, optimizing performance, durability, and on-snow enjoyment.

Core structure

Injection

This process results in skis with an injected core, often made of polyurethane or foam, known for vibration damping and being lighter than traditional wood cores.

Basically, the outer layers of the ski are used as a mold into which foam is injected. It expands and fills the space, meaning the ski’s core is made of foam! It’s easy to imagine how that would differ from a wood-core ski.

While this method is effective for producing more forgiving and accessible skis, it has limitations in responsiveness and long-term durability compared to laminated wood cores, which are the standard in high-performance skis.

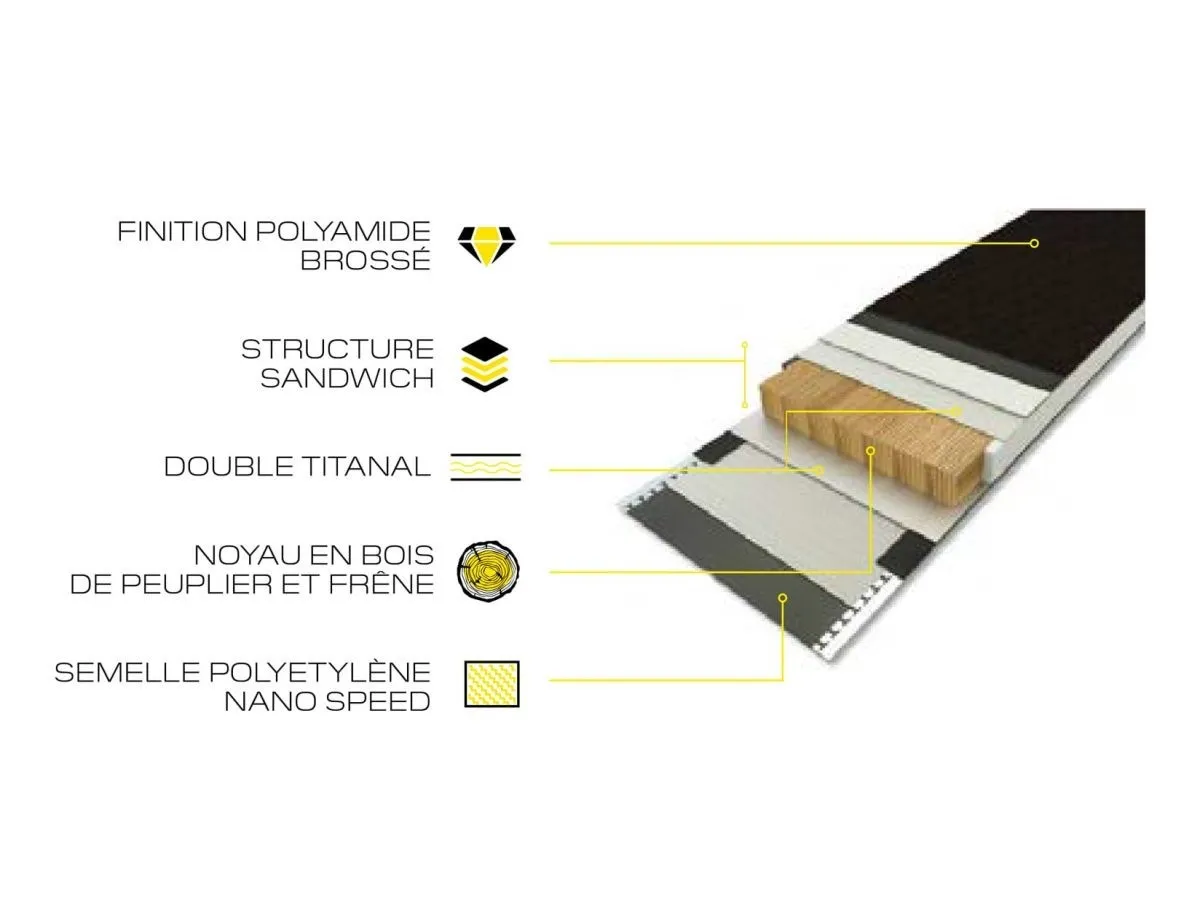

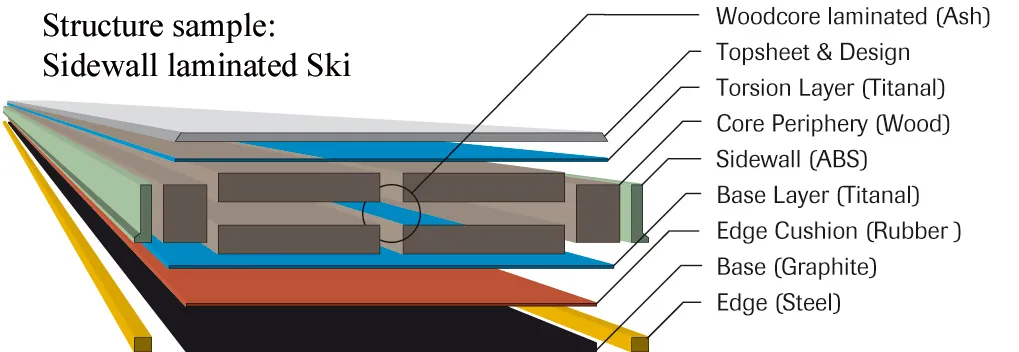

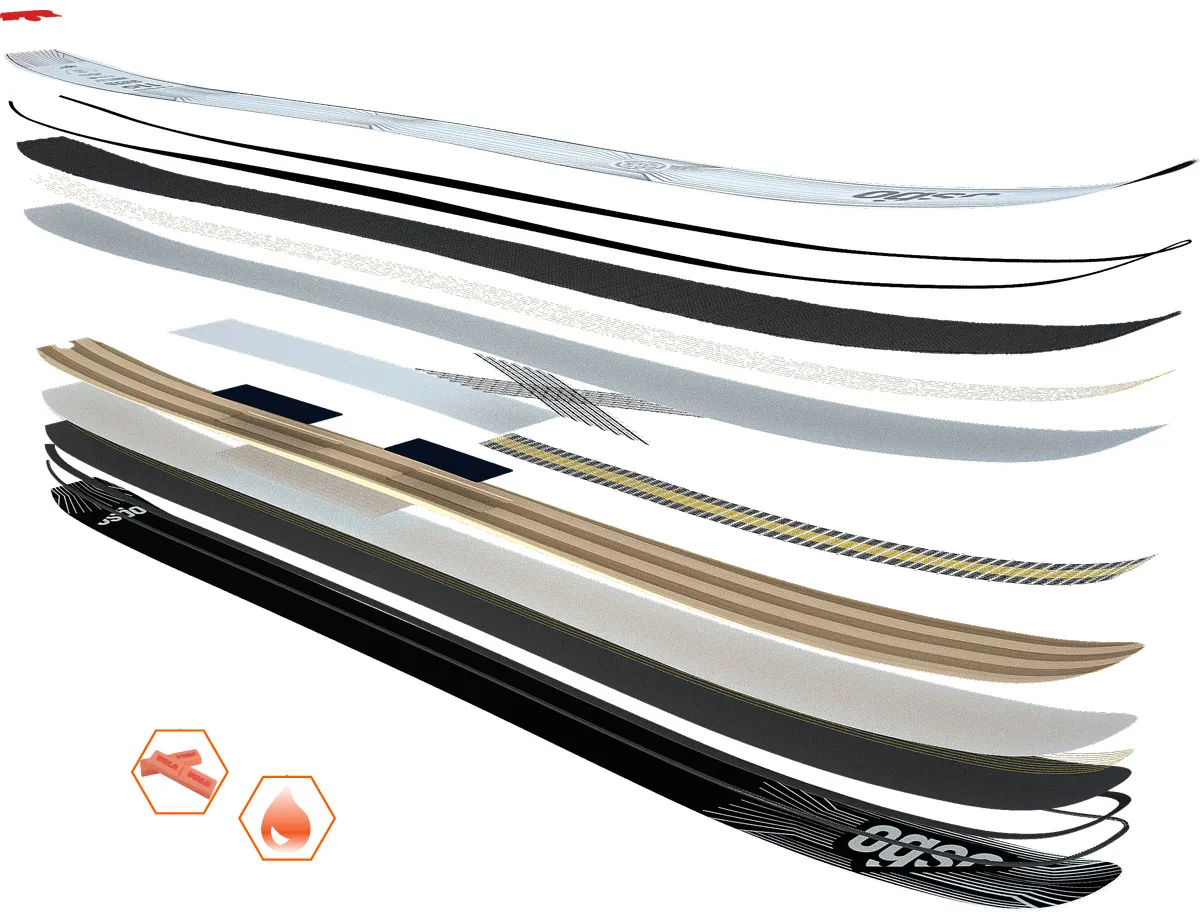

Sandwich construction

Sandwich construction is the traditional method of ski building, where various materials are layered and bonded together to form the ski.

This method is known for enhancing performance by delivering better power transfer and greater precision in turns.

Here are the key elements of sandwich construction:

- Layering of materials:

Materials like wood, metal, fiberglass, or carbon fiber are stacked to form the ski’s core. Each layer has a specific function—stiffness, flexibility, or vibration damping. - Sidewalls:

In sandwich construction, sidewalls are often made from hard materials like ABS (Acrylonitrile Butadiene Styrene) to protect the core and contribute to edge stiffness. - Pressing and heating:

Once the layers are stacked, the ski is pressed in a mold under heat and pressure. This bonds the components into a strong, cohesive structure.

Skis built this way are known for their precision and edge hold, making them ideal for advanced skiers and hard snow conditions.

Sandwich construction also allows customization in material selection, giving designers the ability to tweak performance for specific needs.

It’s considered the gold standard for high-performance skis due to its durability and ability to deliver a precise, responsive skiing experience.

Reinforcement layers

Reinforcement layers play a secondary but important role in ski construction by boosting stiffness, durability, and responsiveness.

Here are the main points about these layers:

- Composition:

Reinforcement layers are made of composite materials like fiberglass or carbon fiber, combined with epoxy resin. Fiberglass is most common for its cost-effectiveness and decent stiffness. Carbon fiber is favored for its lightness and high stiffness, though it’s more expensive. - Function:

These composites provide much of a ski’s stiffness. When combined with the core (usually wood), they contribute to both longitudinal and torsional stiffness, directly affecting how the ski reacts in turns and at high speed. - Manufacturing process:

During production, the fiber (in fabric form) is impregnated with epoxy resin, then applied around the ski core. The whole assembly is heated and pressed so the resin hardens and securely bonds all layers into a solid structure. - Variability: Designers can tweak the quantity and type of reinforcement materials to adjust ski performance. For instance, adding more fiberglass or using carbon fiber increases stiffness—ideal for advanced skiers or hard snow conditions.

Pros and cons

While fiberglass and carbon offer major performance benefits, they can also affect ski weight and cost. Fiberglass is heavier but more affordable and durable. Carbon fiber, though pricier, is lighter, more responsive, and reduces skier fatigue by lowering ski weight.

In short, reinforcement layers are essential in defining how a ski behaves on snow, allowing manufacturers to design skis for a wide range of users and conditions.

The base

The ski base is a key component that directly affects on-snow performance.

It’s usually made from ultra-high molecular weight polyethylene (UHMW-PE4), a high-density plastic known for its durability and glide performance.

This is the part where wax is applied to enhance glide.

The edges

The ski edges are the metal rails that run along the sides of the skis.

They play a crucial role in edge grip, especially on hard-packed or icy snow.

Edges are typically made of hardened steel to withstand abrasion from snow, ice, and sometimes even rocks.

Edges are a key technical element in ski construction, directly impacting skier performance and safety on different terrain types.

Regular and proper edge maintenance ensures better performance, increased safety, and longer ski lifespan.

Protection, top-sheet, and graphics

The protection of the top-sheet, or upper ski layer, is essential for preserving both the integrity and look of the skis.

Top-sheets are not only the ski’s visible face, displaying graphics and branding—they also shield the inner structure from the elements and damage.

To ensure this protection, manufacturers often use protective films during production.

These films are applied after printing and cutting the top-sheets, then laminated to encapsulate graphics and materials.

This process helps maintain visual quality until store delivery, protecting against scratches, impact, and moisture. Once the ski is assembled and pressed at high temperature, the protective film is removed, revealing a flawless top-sheet ready to shine on the slopes.

Camber and rocker

Camber and rocker are key elements in ski design, composition, and structure, greatly affecting snow performance.

Camber

Camber, an upward arch in the middle of the ski (underfoot), promotes stability, better edge grip, and enhanced precision, especially on hard snow, by distributing pressure evenly along the ski’s length.

It’s ideal for skiers looking for a dynamic, responsive experience on groomed trails or firm snow conditions.

Rocker

Rocker, by contrast, is defined by raised tips and tails, improving maneuverability, making turn initiation easier, and providing better float in deep snow. It makes the ski more forgiving and versatile across various terrains, especially powder.

Modern skis often combine both features for versatility across a wide range of conditions.

Camber underfoot ensures solid grip on groomers, while rocker at the tips reduces edge catching and boosts float in powder. This hybrid design lets skiers enjoy a balanced ride—able to carve confidently on hardpack and glide easily in soft snow.

Your comments and questions